Complete guide to selection of Power Transmission Couplings / Industrial Coupling, Couplings for Motor, Pumps, Gear Box, Grinder, Cement Industries, mining Etc.

Power Transmission Couplings:

Whats are Power Transmission Couplings & their uses:

Defination:

- A coupling is device used to connect two shafts together at their ends for the purpose of power transmission.

- It also acts as a fuse between driver (Motor) & Driven (Gear box, Crusher, etc), as it get disconnected at the time when the transmission power exceeds the coupling designed capacity.

Motor & Pump connected through coupling

Requirement for Coupling & its function:

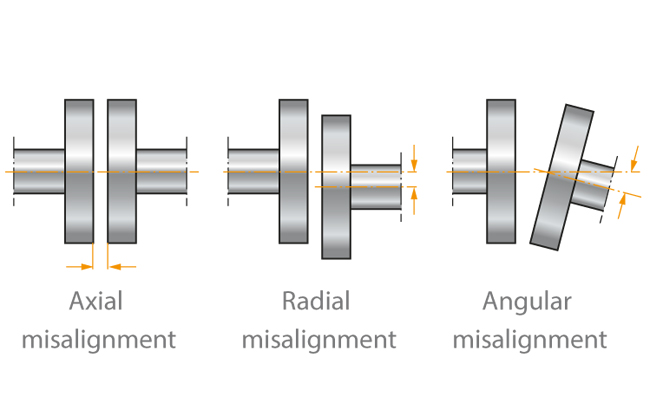

- Accommodates misalignment.(i.e Parallel/Radial, Axial, Angular misalignment).

- Dampen Vibration (by absorbing Shocks), Oscillation.

- Limiting power & torque transmission.

Types of shaft misalignment

Types of couplings commonly used in Industries:

- Star/Jaw Coupling.

- HRC Couplings..

- Pin Bush Couplings (PBC).

- Full Gear Couplings/Half Gear Coupling.

- Tyre Couplings.

- Resilient/Grid Coupling.

- Fluid Coupling.

- Suitable for Simple,Common & non critical applications.

- Accommodates Misalignment (Parallel, Angular & Axial).

- Can cater application with large DBSE (Distance between shaft ends) with spacer arrangements.

- Also available with External Spider Star for immediate replacement of spare without dismounting the coupling.

JAW Coupling

2. HRC Couplings:

- Similar to Star coupling but have comparatively high power rating due to its reliable design.

- Fail safe & can sustain Incidental misalignment.

- Suitable for Flywheel application.

HRC Couplings

3. Pin bush Couplings:

- Simple Construction.

- Easy to be assembled & dissembled.

- Easy to replace spare (without dismounting the coupling).

- Silent & Vibration free (can be used for high power transmission , Vibration).

Pin Bush Couplings

4. Full Gear/ Half Gear Couplings:

- Suitable for area where high torque transmission required.

- Manufactured with Carbon Steel & fine surface finish with flawless dimensional accuracy.

- Can be used in area with High Temp. , Moisture area (can sustain corrosion).

- Comparative to other couplings can sustain large axial misalignment.

Half Gear Coupling

Full Gear Coupling

5. Tyre Coupling:

- Flexible Design.

- Sustain more vibration, torsional oscillations in comparison to other couplings.

- Suitable for application with large Axial, Parallel & Angular misalignment.

- Easy to replace spare (without dismounting the coupling).

Tyre Coupling

6. Grid / Resilient Coupling:

- Sustain high shock.

- Suitable for reversible drive application.

- High Torsional flexibility.

- Easy to replace Grids spare (without dismounting the coupling).

Grid / Resilient Coupling

7. Disc Coupling:

- Suitable for area where high torque transmission required.

- Manufactured with Carbon Steel & fine surface finish with flawless dimensional accuracy.

- Can be used in area with High Temp. , Moisture area (can sustain corrosion).

- Comparative to other couplings can sustain large axial misalignment.

Disc Coupling

8. Fluid / Hydro Coupling:

Fluid / Hydro coupling

Hope this content will help you with the selection of right coupling for your desired application & understanding the types of coupling will help you to select right coupling for your application.

If you like my content please comment & share my blog & have any queries regarding this matter please feel free to consult by commenting.

Thanks & regards

LJ

Comments

Post a Comment